LOOKING TO HAVE A CUSTOM MASK MADE?

Here’s what you need to know…

Pricing is based on the design, size, and style of the mask which in turn defines the amount of time and materials needed to produce your mask.

The main stages of mask making are:

Designing

The design of the mask establishes the size, look and style of your mask. The main styles of masks are the quarter mask (top half of face), half mask (face covered) and full head (pulls over your head). Obviously, the larger you go, the more time and materials needed, as well as added complexities to the process.

We DO NOT do digital renderings and mock-ups of the design first. The design is worked out in the sculpting stage. Rough sketches may be provided to work out more complex concepts.

Sculpting

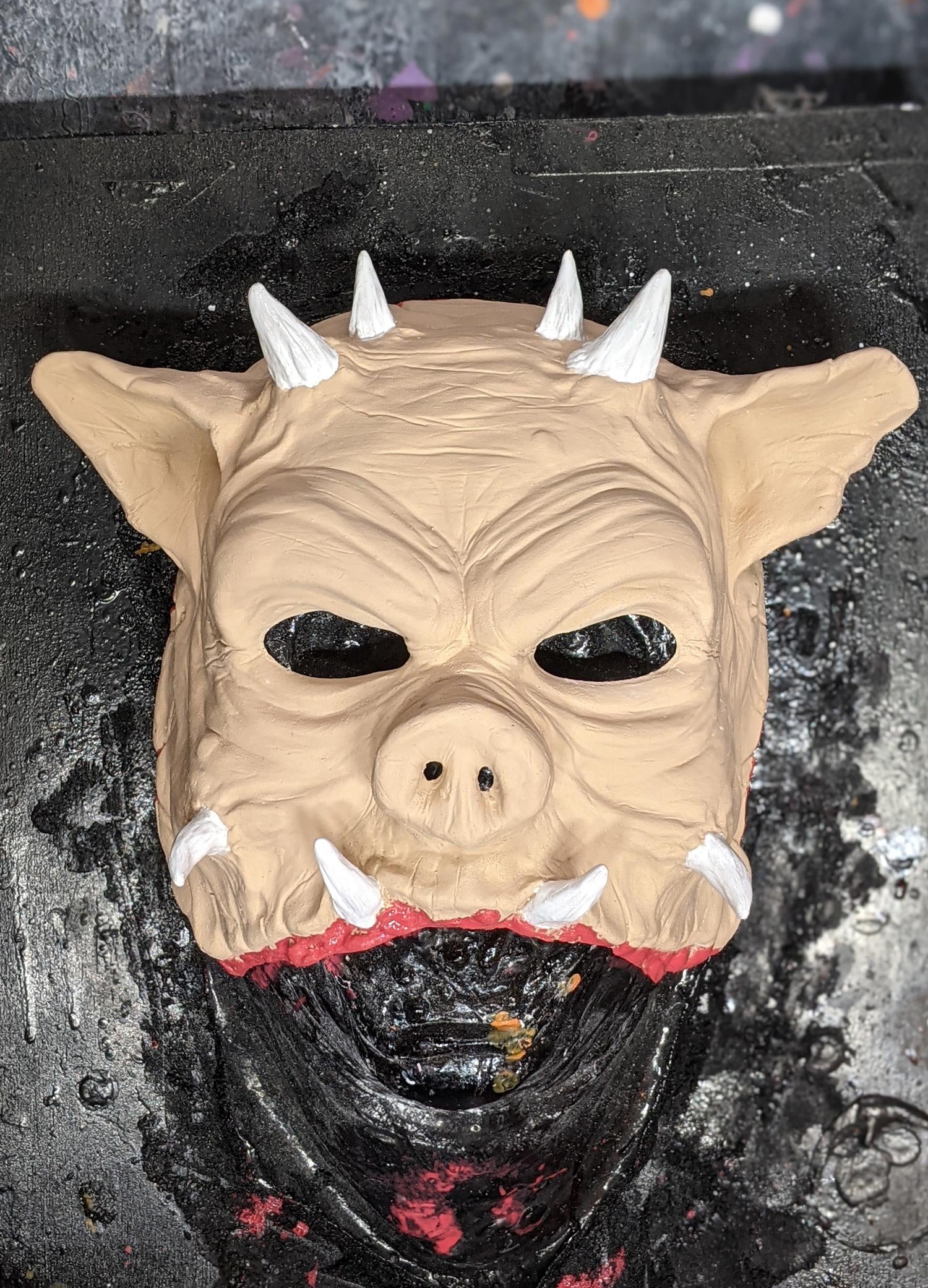

Your design is brought to life with WED Clay and you will be sent pics throughout the process for feedback. Once the sculpt is approved it will be molded and can no longer be changed.

Mold making

The sculpture is molded over with pottery plaster and destroys the sculpture. This master mold can produce around 25+ masks with exceptional detail before any mold erosion will occur. For runs of more than 25, a master copy can be made along with extra molds to expedite the process and maintain quality which can also increase the cost.

Pouring, Pulling, Cutting & Washing

Monster Makers liquid latex is poured into the mold, dwells for 2+ hours, is dripped out, and dried. The raw latex is then cut and washed to prep it for the painting stage.

Painting

A combination of latex paints and acrylic inks are sprayed and/or brushed onto the prepped latex masks bringing them to life. The complexity of the paint job and the amount of colors and steps needed to achieve the desired effect also affect your pricing. A two-color simple scheme like the Bango Skank (red) mask is less time and material intensive than a hand-painted and air-brushed scheme like ‘They Live’.

Strapping

Depending on the style of mask it will need to be strapped and there are many different ways to achieve this. The standard is an elastic strap permanently affixed to the mask via heavy-duty snaps. This works well for the majority of heads and allows for some flexibility in size.

Other options include leather straps with grommets, thicker straps, dual straps, adjustable leather or elastic with snap options, and so on. Send us examples of what you have in mind and we can discuss what is best.

Finishing

All masks come tagged, bagged, numbered, and signed. Additional options include having us design a custom tag for your mask, care instructions, and custom stickers or packaging.

Shipping

Shipping costs will be outlined in your quote. The larger, heavier, and more quantity of masks all affect your final cost. Preferred methods are USPS for smaller orders, and UPS for larger orders.

What else you need to know…

Payment: We request half of the quote as a down payment to begin the project and the remaining half due upon approval of the final products to initiate shipping.

Timelines: 30-60 days is the typical range for an order of 25 masks. The timeline will be set once the scope of your project is defined.

Rights & Ownership: With this kind of custom order the pricing includes exclusive rights for you, the buyer, to own and resell your product and it will not be recreated or sold by Philbrix Studioz. Shared ownership or rights to specific variants or colorways are also options we can discuss if you are not as concerned with exclusivity.

One-offs vs Production Runs: Due to the extensive process as noted above you can see that the majority of the heavy lifting comes in sculpting and molding your mask which lends itself well for short-run production. Once the mold is made the time investment is not as drastic for making one versus five masks. If you’re looking to have just one mask made for yourself that no one else has, consider creating different variants or reselling a small batch as you’ll pay about the same for 5 masks as you would for 1.

Additional Production Requests & Quantity Breaks: With the design set and mold made additional quantities can be made at a quicker pace and cost becomes a ‘per mask’ price as the design, sculpt, and rights are covered in the initial creation cost.

What Is Done With the Mold?

The mold will be held at Philbrix Studioz so that additional masks can be made for you in the future at your request. If the mold is not used within 2 years you will be contacted to make arrangements on what can be done with it. Whether that be trashing it or partnering to possibly make more for resale. If you would like to arrange to purchase your mold, an arrangement can be made.Any further questions? Let us know in the comments box below.

Thank you for your interest in working with Philbrix Studioz and Gravity Bleeds. The information submitted is ONLY for quoting purposes and will not be reused, resold, or violated in any way.